In Southeast Asia, countries like Indonesia, Malaysia, and Vietnam are blessed with rich forest resources and vast coconut and palm plantations. These tropical lands yield millions of tons of coconuts and palm fruits every year, fueling industries from food and beverages to cosmetics and biofuels. But while the world enjoys fresh coconut water and palm oil, what happens to the waste?

A surprisingly large portion of the by-products—especially coconut husk fibers (coir) and palm oil residues—are either underutilized or simply discarded. This not only leads to environmental burdens, such as land pollution and unmanaged biomass waste, but also represents a missed economic opportunity.

At WATTMECH, we’ve been exploring how to fully utilize our 3000-ton hydraulic press machine to extract greater value from biomass materials. Through collaboration with clients and repeated testing, we’ve developed two highly feasible, profitable solutions: turning coconut husks and palm oil waste into presswood pallets and pressed boards.

1. Presswood Pallets from Coconut Coir and Palm Residue: A Smart Alternative to Solid Wood

Many Southeast Asian countries are export-driven, with manufacturing plants requiring large quantities of wooden pallets for logistics and shipping. However, the rising cost of solid wood and growing restrictions on fumigation make traditional wooden pallets less attractive.

Here’s where presswood pallets come in.

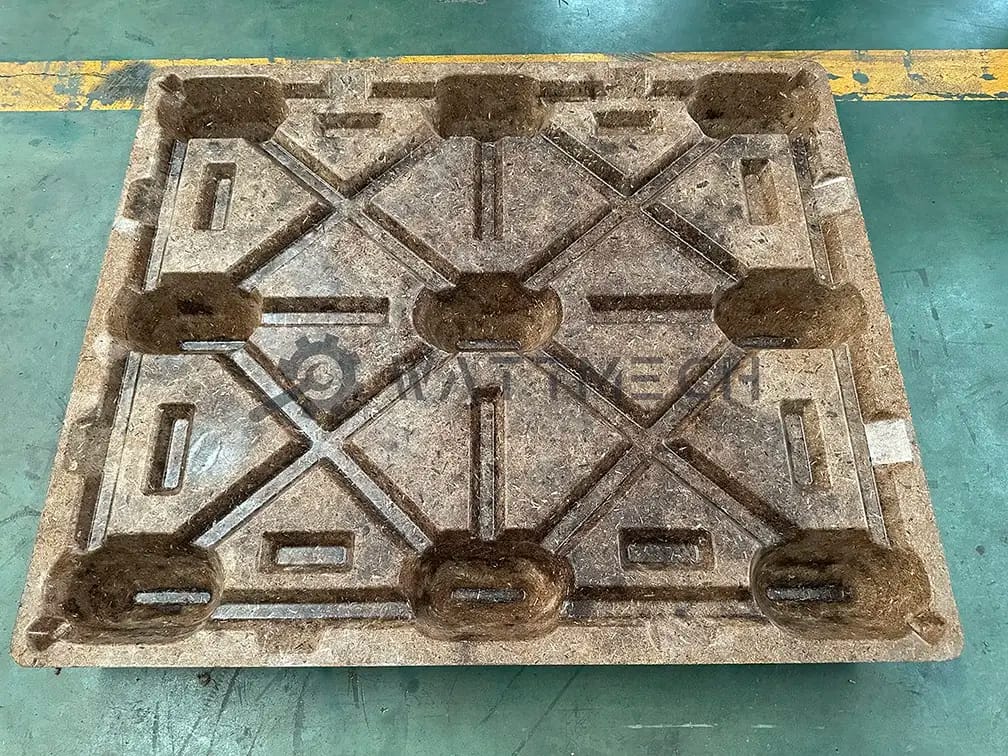

By using coir fibers and palm oil waste as raw material, combined with eco-friendly adhesives, our 1600-ton presswood machine can mold these into high-strength pallets. Coir has excellent fiber integrity, allowing molded pallets to withstand dynamic loads of up to 3 tons. The high pressure ensures tight bonding and water resistance—critical for storage and international shipping.

Moreover, since pressed pallets do not require fumigation, they comply with international ISPM-15 export regulations, making them ideal for export businesses in Southeast Asia.

In short:

- 🌱 Made from renewable waste

- 💪 Strong and durable (up to 3-ton dynamic load)

- 🌊 Water-resistant

- 🚫 No fumigation required

- 💰 Lower cost than solid wood

These molded pallets are not just environmentally responsible—they’re a smart business decision.

Posts related to presswood pallets:

1. Pressed Pallets Production Raw Material

2. Presswood pallets for single-use: A sustainable solution for export packaging.

3. Molded pallets outperform traditional wooden pallets

2. Pressed Fiber Boards: A New Frontier in Furniture and Construction Materials

Traditionally, particleboard, MDF, and plywood dominate the furniture and interior decoration industries. But these materials often rely on wood chips and high energy consumption during processing.

Inspired by one of our clients who successfully used wheat straw in our 3000-ton pallet molding machine to produce construction panels, we began experimenting with coconut fiber. The results were beyond our expectations: the fiberboards produced from crushed coconut husk were smooth, rigid, and remarkably strong.

These boards can be used in:

- 🪑 Furniture manufacturing

- 🏠 Interior wall panels and ceiling tiles

- 📦 Packaging materials

- 📚 Eco-friendly DIY projects

By substituting coconut coir and palm residue for traditional wood fibers, manufacturers not only reduce their raw material costs but also contribute to reducing deforestation and carbon emissions.

Southeast Asia: A Hotspot for Bio-Based Innovation

The potential to transform agricultural waste into high-value products is particularly promising in Southeast Asia. With a steady supply of biomass and a booming demand for eco-packaging and low-cost building materials, the region is poised to become a global leader in sustainable manufacturing.

At WATTMECH, we leverage our expertise in customizing high-pressure molding machines to suit different raw materials and end products. Whether it’s pallets, boards, or other molded components, we help clients unlock the full value of their local resources while promoting environmental sustainability.

Conclusion: From Waste to Wealth, Powered by Technology

Turning coconut husk and palm oil residues into valuable products isn’t just possible—it’s practical, scalable, and profitable. With the right equipment and guidance, businesses in Southeast Asia can reduce waste, lower costs, and create eco-friendly products that meet international standards.

If you’re looking for a partner to help you transform biomass waste into business opportunities, contact us at PalletsBiz. Our team is ready to provide tailor-made solutions backed by industry experience and technological know-how.

Click here to know: How to Choose the Right Molded Pallet Press and how to figure out the suitable press machine pressure?