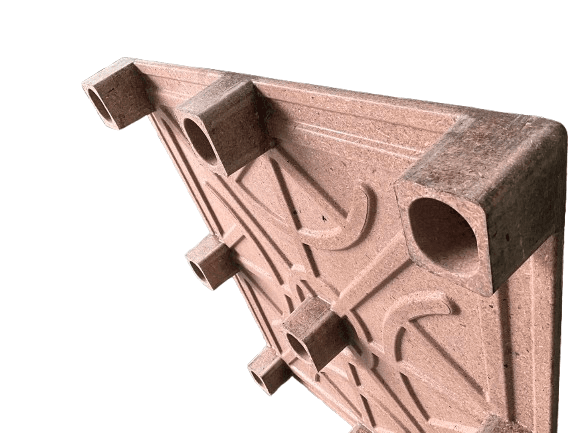

Presswood pallets may have burrs along their edges, which can result from two primary factors:

1. Mold Wear and Press Machine Deformation

After prolonged use, molds undergo wear, and presswood pallet press machine structures may slightly deform. This can lead to inaccurate mold alignment, allowing wood fibers to get trapped between the upper mold and the mold cavity, resulting in burrs.

2. Inadequate Mold Precision

Due to variations in machine structures and manufacturing technologies, some presswood pallet machines lack high precision, leading to misalignment during mold closing. To prevent machine damage caused by improper alignment, some manufacturers design molds with larger tolerances, increasing the gap between the upper mold and the cavity. However, this greater tolerance also contributes to burr formation.

Why Choose a Three-Beam, Four-Column Press Machine?

A three-beam, four-column presswood pallet machine uses four guiding columns to ensure precise mold alignment. This structure enhances stability, prevents frame deformation, and provides greater accuracy compared to frame-type presses.

How to Remove Burrs from Presswood Pallets?

- For thin and minimal burrs: Simply wearing gloves and rubbing the edges can remove them.

- For thicker burrs: Manual removal becomes difficult, so using an angle grinder or specialized edge-trimming machines is recommended.

Find the Best Presswood Pallet Machine Manufacturer

For high-quality presswood pallet machines, choose PalletsBiz and PresswoodMachine, leading manufacturers in the industry. PalletsBiz is a pioneer with a full supply chain, offering complete solutions from press machine design to mold manufacturing.

👉 Contact them today to get the best presswood pallets production solutions!