Molded pallets, crafted from materials like wood fiber and resin, are gaining significant traction across various industries. Their lightweight design, durability, and moisture resistance have led to a rapid increase in their adoption by businesses seeking efficient and cost-effective material handling solutions. The versatility of molded pallets allows them to be tailored for specific needs across diverse sectors.

Let’s explore the different styles of molded pallets available:

1. Nine-Leg Presswood Pallets

The nine-leg presswood pallet represents the most traditional and common style. These affordable molded pallets are typically manufactured using pallet molding machines with pressure capacities ranging from 800 to 1600 tons, with 1250-ton or 1600-ton presses being recommended for optimal production. The manufacturing process is straightforward, involving a single compression molding cycle with specialized Presswood pallet MDI glue. Production rates typically range from 10 to 15 pallets per hour. Individual pallet weights can vary from 10kg to 25kg, with dynamic load capacities ranging from 500kg to 2500kg. A significant advantage of these nestable molded pallets is their stackability. Approximately 41 pallets can be stacked to a height of 2 meters, resulting in substantial savings on transportation and storage costs. However, the nine recessed “feet” on the pallet surface can pose challenges for certain items like beverage bottles or cardboard boxes. Additionally, these non-roller conveyor molded pallets are not ideal for use on production line roller conveyors.

For information regarding the container loading capacity of nine-leg molded pallets, you can refer to this article: Nine-Leg Molded Pallet Container Loading Quantity

2. Double-Deck Presswood Pallets

The double-deck molded pallet is an improved design based on the nine-leg style. While it can be produced using the same range of pallet molding machines (800 to 1600 tons), its construction involves combining two molded sections (top and bottom). This results in a weight that is 1.2 to 2 times that of a standard molded pallet. Consequently, the production of these strong molded pallets typically requires at least two molding presses to manufacture the components, halving the production efficiency compared to single-piece pallets. The double-deck design allows for the reduction or even elimination of surface recesses, making this roller conveyor-compatible molded pallets suitable for use on automated conveyor systems and also stable for racking applications. They also offer good dynamic load-bearing capacity.

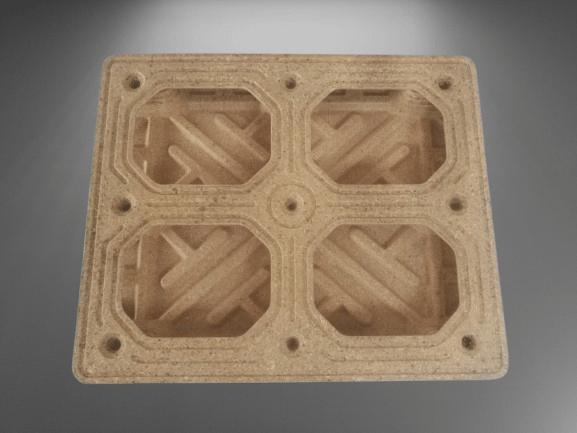

3. Rackable Presswood Pallets

Similar in appearance to the nine-leg molded pallet, the key advantage of rackable molded pallets lies in their ability to be safely used in warehouse racking systems. These automated conveyor systems molded pallets are also designed for compatibility with automated roller conveyors, offering versatility in material handling.

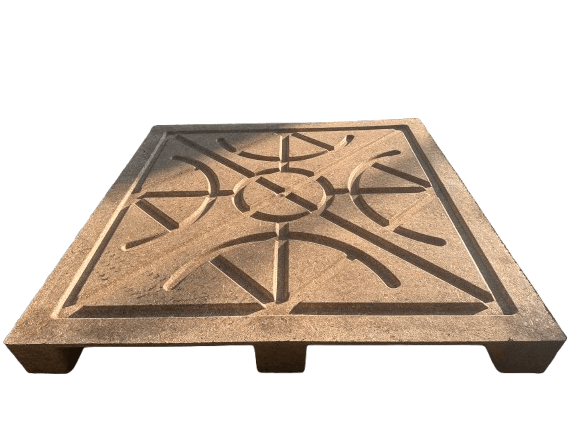

4. Flat-Surface Presswood Pallets

The flat-surface presswood pallet is a newly developed style by PalletsBiz. Featuring a specially designed mold and produced using a 1600-ton press with specialized MDI glue, it achieves a production rate of 10-15 pallets per hour. Weighing between 15 to 25kg and offering a load capacity of 500kg to 2500kg, this smooth surface molded pallet boasts a completely flat top surface and exceptional load-bearing capabilities. This versatile molded pallet can accommodate virtually any type of goods and provides superior protection against damage. Furthermore, with simple modifications, it can also be adapted for use on automated roller conveyors. This popular molded pallet style is currently one of the most sought-after options in the market.

5. Solar Panel Presswood Pallets

Specifically designed by PalletsBiz to meet the needs of solar panel manufacturers in China and Southeast Asia, these large format molded pallets can reach dimensions of up to 2500x1300mm and weigh between 45-50kg. Their stackable design significantly reduces transportation and warehousing costs. Compared to traditional wooden solar panel pallets, these lightweight solar panel pallets offer a weight advantage and are more cost-effective. PalletsBiz has already secured its first international order for these specialized molding machines with a customer in Vietnam.

PalletsBiz and PresswoodMachine are continuously engaged in research and development to create new molded pallet styles that cater to the diverse needs of customers across various industries and applications. For any inquiries or requirements regarding custom molded pallets or molded pallet manufacturing, please contact PalletsBiz, a leading innovator and pioneer in the molded pallet machinery industry.