Using pallets on roller conveyors is a common requirement in automated production and logistics environments. However, not all pallet types are suitable for this application. One common question we receive is: Can presswood pallets be used on roller conveyors?

The short answer is: Yes, with the right design adjustments.

Challenges with Standard Presswood Pallets on Roller Conveyors

Standard nine-leg presswood pallet (also called nestable pallet) are not ideal for roller conveyors due to their design and leg structure. These pallets have gaps between the legs and limited contact area with the rollers. When placed on a roller conveyor, they often shake, wobble, or even cause items to fall off due to the uneven support.

But with some modifications or specially designed alternatives, presswood pallet can perform efficiently on roller conveyors.

Presswood Pallets Suitable for Roller Conveyors

1. Nine-Leg Pallets with Wooden Strips

One simple and cost-effective solution is to attach three wooden beams underneath the standard nine-leg presswood pallet. Each beam connects three legs, creating a more stable base. This modification:

- Increases the contact area with the rollers

- Prevents wobbling

- Provides better load stability

This is an ideal retrofit for existing pallets and allows for smoother operation on conveyor systems.

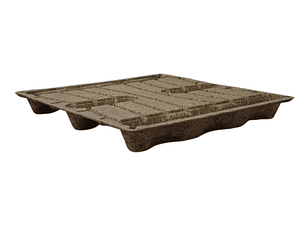

2. H-Type Presswood Pallets

H-Type presswood pallet are specially engineered with three continuous longitudinal legs at the base. This unique design:

- Ensures consistent contact with roller conveyors

- Eliminates the need for additional reinforcement

- Supports racking applications as well

These pallets are ideal for medium to large factories with continuous production lines or automated material handling systems.

We also offer a new extra-large version of the H-type pallet-Solar Panel Pallets, designed specifically for transporting solar photovoltaic panels. This pallet maintains the same roller compatibility while accommodating oversized loads.

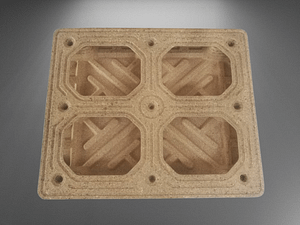

3. Grid Type Presswood Pallets (“田”-shaped bottom)

This pallet style consists of two sections fastened with nails, forming a square grid-like base (“田” shape). While heavier and more complex to manufacture, it provides:

- Stronger load-bearing capacity

- Excellent stability on roller conveyors

It’s a preferred choice in industries requiring heavy-duty and durable pallets.

Conclusion

Can presswood pallet work on roller conveyors? Absolutely—with smart design adaptations. All of the pallet types listed above are engineered to increase contact surface with rollers, minimizing vibration and enhancing stability during transport.

For facilities with automated conveyor systems, these specially designed presswood pallet for roller conveyors offer both cost savings and improved efficiency.

Ready to Upgrade Your Conveyor System with Presswood Pallets?

Whether you’re looking to retrofit your existing pallet or need ready-made H-type presswood pallet for your automated production line, we’ve got the perfect solution for you.

👉 Contact us today to get expert advice or request a free quote.

Let’s help you streamline your operations with conveyor-compatible presswood pallet built for performance and efficiency.

📞 Call Us | 📧 Email Us | 🛒 Shop Presswood Pallet Now

FAQ: Presswood Pallets on Roller Conveyors

Q1: Why do standard nine-leg presswood pallets wobble on roller conveyors?

A: Due to gaps between the pallet legs and insufficient surface contact with rollers, causing instability.

Q2: Can I modify existing presswood pallets to use on a conveyor?

A: Yes. Adding wooden strips underneath the legs can stabilize them for conveyor use.

Q3: Are H-type presswood pallets better for roller systems?

A: Yes, they are designed with continuous legs for smooth and stable operation on conveyors and racks.

Q4: What’s the best presswood pallet for transporting large items like solar panels?

A: Our custom large H-type presswood pallet are ideal for solar panel transportation on roller conveyors.