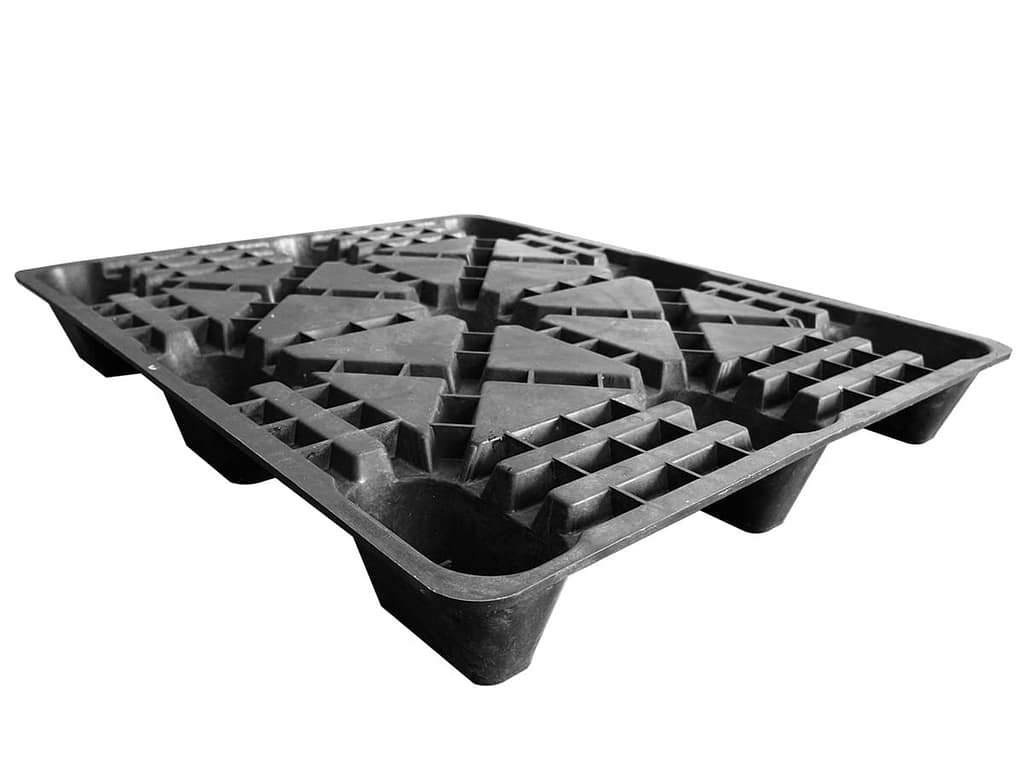

Nested Pallets

Pallet Specifications

Raw Material: Wood Waste, Wood Scrips, Wheat Straw, Rice Husk, Coconut Fiber, Flax, Palm Branches

Pallet Size: 600x800mm,1200x800mm, 1200x1000mm, 1100x1100mm, 1200x1200mm,

Dynamic Load: 500Kg-2500Kg,

Static Load: Max 13000 Kg

Glue Ratio: UF-15% or MDI 4-5%

4 Way & 2 Way Entry

Pallet Weight: 10Kg-25Kg

Description:

Molded Wood Pallet Features & Benefits:

Cost-Effective Solution for Your Pallet Needs: Our Molded Presswood Pallets present a highly cost-effective alternative to traditional wooden and plastic pallets. They can be reused multiple times, significantly reducing the cost per shipment. This makes them an economical choice for businesses looking to optimize their shipping expenses.

Lightweight Yet Durable Construction: Weighing 60% less than conventional hardwood pallets, these pallets don’t sacrifice strength. Their durability allows for repeated use, and their affordability means they can be easily replaced if lost, making them perfect for return and reuse programs where pallet management can be challenging.

Nestable and Space-Saving Design: With a remarkable space-saving ratio of 4-1, our pallets offer substantial savings in both warehouse space and shipping costs. Their nestable design simplifies handling and storage, enhancing overall operational efficiency.

Cargo Protection and Safety Features: The one-piece design, devoid of nails or staples and featuring rounded corners, not only safeguards your products and packages from damage but also minimizes the risk of injuries to employees and customers during handling. This design aspect contributes to a safer and more reliable shipping process.

Export-Ready without Hassles: Unlike many pallets, our Molded Presswood Pallets are not subject to IPPC-ISPM 15 regulations as they are classified as “processed wood”. The high-heat manufacturing process eliminates the necessity for additional pest treatments for overseas shipping, ensuring seamless export to any country.

Environmentally Conscious and Sustainable: These pallets are produced using a high heat and pressure process that transforms damaged logs, wood waste, and other wood by-products into new, functional pallets, consuming less energy in the process.

Ideal Applications: Due to their absence of nails, insect pests, mold, and fungus, Molded Wood Pallets are the preferred choice for various industries.