In a recent visit to a large grain and oil company, we had the opportunity to sit down with the production manager and head of storage and transportation to discuss how they could optimize their current logistics and packaging systems. The company was actively searching for alternatives to improve productivity and reduce operational costs, which led to an insightful discussion about its current use of plastic pallets.

The Challenges with Plastic Pallets

One of the main issues identified with their existing plastic pallets was their lack of flatness. This made it difficult for automated robots to efficiently pick up goods, resulting in multiple trips to pack and unpack items. The inefficiency led to significant manpower wastage, time delays, and higher operational costs.

The Need for Rice Husk Presswood Pallets

The company also shared an interesting detail: they have an abundant supply of rice husks, a byproduct of their grain processing, which they hoped to repurpose into a more cost-effective solution for food packaging and transportation. This gave us the perfect opportunity to introduce them to a new, environmentally friendly alternative: rice husk presswood pallets.

The Advantages of Rice Husk Presswood Pallets

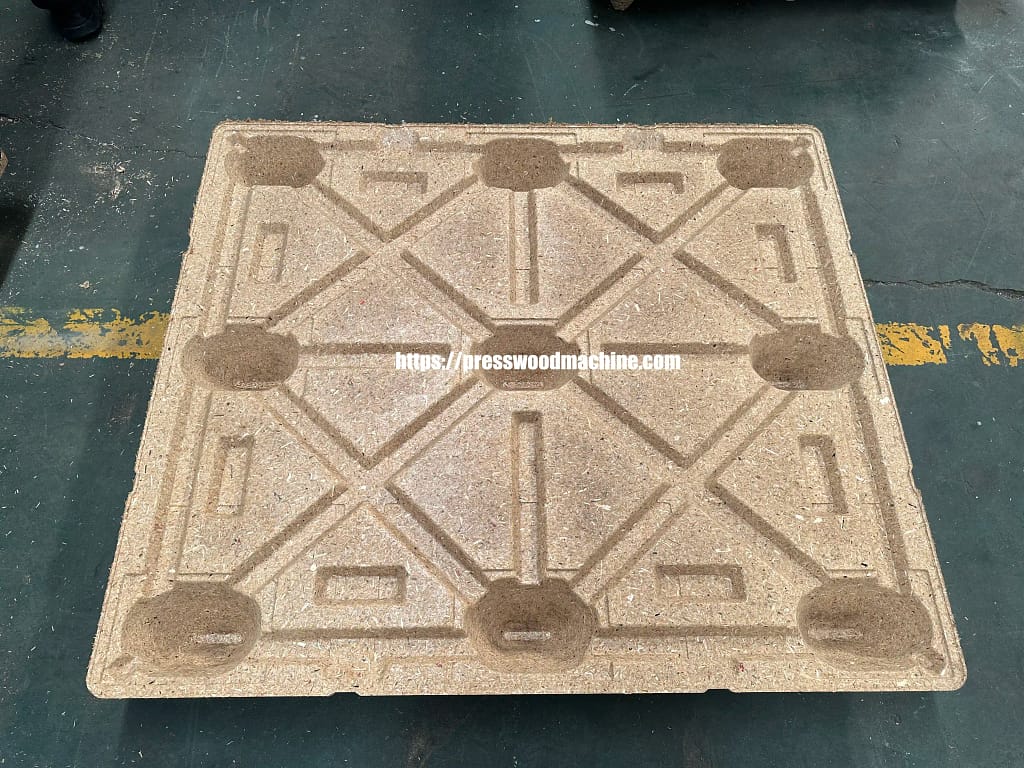

At PalletsBiz, we specialize in providing high-quality presswood pallets that are manufactured using innovative pallet molding machines. Our molded pallets are created using natural rice husk fibers, making them not only durable but also eco-friendly. Here’s why our rice husk compressed pallets are the ideal choice for companies like this grain and oil giant:

- Enhanced Loading Capacity

The integral molding of these pressed pallets results in a highly stable structure that can carry heavier loads without compromising strength. This robust design ensures that our pallets can easily accommodate a variety of goods, from raw grains to packaged products, ensuring better efficiency and reduced downtime during transportation. - Eco-Friendly and Biodegradable

Using rice husk fibers as the primary material for Presswood pallets is a sustainable solution that significantly reduces environmental impact. Unlike plastic pallets, which take hundreds of years to break down, rice husk molded pallets are completely biodegradable. When damaged or no longer needed, they will naturally decompose without harming the environment, making them an ideal choice for companies looking to reduce their carbon footprint. - Waterproof and Moisture-Proof

The press molding process ensures that our compressed pallets have superior waterproof and moisture-proof properties, making them suitable for use in diverse climates and conditions. Whether exposed to rain, high humidity, or extreme temperatures, these pallets maintain their strength and integrity, protecting goods during storage and transportation.

Why Choose Presswood Pallets for Your Business?

For businesses in industries such as grain, food processing, and other bulk goods logistics, choosing the right pallet is crucial to maintaining an efficient, cost-effective supply chain. Our pallet molding machines ensure that every pressed pallet is made with precision and consistency, offering the following benefits:

- Durability: Our molded pallets have a high level of load-bearing capacity, making them ideal for heavy-duty use in warehouses and transportation.

- Cost-Effective: Rice husk as a raw material is both abundant and affordable, leading to reduced costs compared to traditional plastic or wood pallets.

- Customizable Designs: We offer customizable options for presswood pallet machines, allowing businesses to create pallets that best fit their specific needs in terms of size, shape, and strength.

Looking Toward a Sustainable Future

After thoroughly addressing their concerns and questions, the customer showed a keen interest in integrating rice husk presswood pallets into their operations. They are eager to move forward and requested more technical support to optimize their pallet system.

We are excited about the opportunity to collaborate with them and introduce our innovative pallet solutions. By using rice husks, companies can not only save on material costs but also contribute to a more sustainable future for the logistics and transportation industry.

If you’re interested in learning more about presswood pallets and how they can benefit your business, we invite you to visit our website at PalletsBiz or contact us for personalized advice on selecting the right pallet molding machine for your needs.